THE WHEATON®

ROLLER SYSTEM

WHEATON® roller bottle culture apparatuses have long since been appreciated for their excellent performance in laboratory, pilot plant and production cell culture installations.

We understand that control, monitoring and documentation are vital for every cell culture application. That's why our state-of-the-art instruments are designed to support. industry-standard communication protocols to facilitate integration into new production facilities. They also feature a USB downloadable system event log for accurate process documentation.

Our system is rounded off by an extensive range of roller bottles in various sizes and with different closure configurations, as well as incubators optimally matched to the roller apparatuses.

All this to provide you with optimum support in your daily work.

The PERFECT combination

ROLLER BOTTLES

ROLLER APPARATUSES

INCUBATORS

ROLLER BOTTLES

APPLICATIONS

- Adherent cell roller culture

- Vaccine production

- To use with WHEATON® Roller Apparatus

FEATURES & BENEFITS

- Specifically designed for adherent cell roller culture

- Reusable roller bottles

- Glass is specially selected for optical clarity, interior surface smoothness, and the absence of glass imperfections

- Withstands repeated wet or dry sterilization cycles

- Material: Borosilicate glass 3.3 that conforms to USP Type I and ASTM E-438 Type I, Class A requirements

- Autoclavable

- Available in different sizes and with different cap configurations

WHEATON® ROLLER BOTTLES

Ordering information

| Description | Diameter x flat overall length [mm] | Usable surface area [cm²] | Surface [cm²] | Capacity approx. [mL] | Pack Qty | Cat. No. |

|---|---|---|---|---|---|---|

| Roller bottle with 38 mm deep skirted, black phenolic screw cap with white styrene-butadiene rubber liner (GPI 38-415) |

110 x 240 | 550 | 680 | 1380 | 4 | 348252 |

| 110 x 285 | 700 | 840 | 1760 | 4 | 348253 | |

| 110 x 480 | 1320 | 1500 | 3450 | 4 | 348256 | |

| 110 x 550 | 1555 | 1680 | 4230 | 4 | 348258 | |

| Roller bottle with 45 mm white polypropylene screw cap with inner sealing ring and polypropylene pour ring. |

110 x 240 | 550 | 680 | 1380 | 4 | 348272 |

| 110 x 285 | 700 | 840 | 1760 | 4 | 348273 | |

| Roller bottle with 51 mm black phenolic screw cap with shallow skirt and white styrene-butadiene rubber liner (GPI 51-400) |

110 x 270 | 700 | 840 | 1760 | 4 | 348522 |

| 110 x 355 | 940 | 1070 | 2500 | 4 | 348524 | |

| 110 x 535 | 1555 | 1680 | 4230 | 4 | 348528 |

STANDARD & R2P™ 2.0

ROLLER APPARATUS

APPLICATIONS

- Cell culture

- Larger R&D facilities

- Large-scale vaccine production

FEATURES & BENEFITS

- Multiple decking and capacity configurations for high process flexibility

- Smooth ramping and digitally controlled rotation accurate to 0.01 RPM

- Maintenance free precision brushless motor

- Top or bottom mount display for both roller apparatus available

- WHEATON® Standard Roller with bright LED display

- WHEATON® R2P™ 2.0 Roller with robust color touch screen

SPECIALS OF THE R2P™ 2.0 SYSTEM:

- Rotation alarm and temperature alarm ensures process conformity

- Capable of remote interface and monitoring through SCADA systems

- USB downloadable system event log for process documentation

- Robust color touch screen

- Readily recognized icons for intuitive navigation

is equipped with a bright LED display

(top or bottom mounted)

Both roller apparatus are available

in different sizes and with

top or bottom mounted display

EXTREMELY INTUITIVE!

THE R2P™ 2.0 COLOR TOUCH SCREEN

The R2P™ 2.0 touchscreen is designed for use right out of the box. The main screen displays all important process conditions, including bottle speed, bottle direction, alarms, device identification number, power status, and network status.

All parameters are changed in configuration screens that feature large numeric keys and intuitive operation. All screens can access an onboard user guide that details the function of each icon. Don’t worry we will still include the user manual; you just may never need it.

(top or bottom mounted)

Specifications

| Specifications | WHEATON® Standard Roller Apparatus | WHEATON® R2P™ 2.0 Roller Apparatus |

|---|---|---|

| Capacity | 5–88 positions | 5–88 positions |

| Bottle speed | 0.25–8.1 RPM (110 mm bottle, other speeds available) | 0.25–8.1 RPM (110 mm bottle, other speeds available) |

| Bottle diameter | 108–121 mm | 108–121 mm |

| Bottle length | up to 550 mm | up to 550 mm |

| Accuracy | 0.01 RPM | 0.01 RPM |

| Drive | Belt driven | Belt driven |

| Motor type | Brushless DC | Brushless DC |

| Rotation direction | Clockwise and counter-clockwise | Clockwise, counter-clockwise and rocking |

| Rotation alarm | Optional | Included |

| Options | Rotation alarm and battery backup | Temperature monitoring and battery backup |

| Remote communication | Dry contact relay | Yes, Modbus® Protocol and WHEATON® Protocol via Ethernet TCP/IP and RS422/485 |

| Operating temperature | 10 °C to 40 °C | 10 °C to 40 °C |

| Humidity | 80% up to 31 °C | 80% up to 31 °C |

| Electrical | 100–240 VAC, 50/60 Hz, 35 W | 100–240 VAC, 50/60 Hz, 35 W |

| Complies with industry standards including UL, CSA, CE, WEEE, and RoHS. | |

WHEATON® STANDARD & R2P™ 2.0 ROLLER APPARATUS

Ordering informationfor most commonly used roller apparatus

Bottom drive — Production spacing

| Control system | # positions | # decks | # of bottle positions | Width (inch / cm) | Depth (inch / cm) | Height (inch / cm) | Weight (lb / kg) | Cat. No. |

|---|---|---|---|---|---|---|---|---|

| R2P™ 2.0 | 5 | 1 | 5 | 31 / 79 | 25 / 63 | 14 / 35 | 52 / 24 | WRBPF5010-[*] |

| R2P™ 2.0 | 5 | 3 | 15 | 31 / 79 | 25 / 63 | 26 / 65 | 85 / 39 | WRBPF5030-[*] |

| R2P™ 2.0 | 5 | 11 | 55 | 31 / 79 | 25 / 63 | 74 / 187 | 217 / 99 | WRBPF5110-[*] |

Bottom drive — Modular spacing

| Control system | # positions | # decks | # of bottle positions | Width (inch / cm) | Depth (inch / cm) | Height (inch / cm) | Weight (lb / kg) | Cat. No. |

|---|---|---|---|---|---|---|---|---|

| R2P™ 2.0 | 5 | 3 | 15 | 30 / 76 | 25 / 63 | 29 / 74 | 112 / 51 | WRBMR5030-[*] |

| Standard | 5 | 3 | 15 | 30 / 76 | 25 / 63 | 29 / 74 | 112 / 51 | WSBMR5030-[*] |

| R2P™ 2.0 | 5 | 7 | 35 | 30 / 76 | 25 / 63 | 57 / 145 | 196 / 89 | WRBMR5070-[*] |

| Standard | 5 | 7 | 35 | 30 / 76 | 25 / 63 | 57 / 145 | 196 / 89 | WSBMR5070-[*] |

| R2P™ 2.0 | 5 | 9 | 45 | 30 / 76 | 25 / 63 | 71 / 179 | 238 / 108 | WRBMR5090-[*] |

| Standard | 5 | 9 | 45 | 30 / 76 | 25 / 63 | 71 / 179 | 238 / 108 | WSBMR5090-[*] |

Top drive — Production spacing

| Control system | # positions | # decks | # of bottle positions | Width (inch / cm) | Depth (inch / cm) | Height (inch / cm) | Weight (lb / kg) | Cat. No. |

|---|---|---|---|---|---|---|---|---|

| R2P™ 2.0 | 5 | 11 | 52 | 31 / 79 | 25 / 63 | 75 / 190 | 250 / 113 | WRTPF5110-[*] |

| Standard | 5 | 11 | 52 | 31 / 79 | 25 / 63 | 75 / 190 | 250 / 113 | WSTPF5110-[*] |

WHEATON® STANDARD & R2P™ 2.0 ROLLER APPARATUS

Part numbering system for further roller apparatus configurations

DWK Life Sciences specializes in standard and customized roller apparatus units. The part numbering system below allows for the configuration of a standard system. The main components that make up a unit include the control system, the size and type of roller bottle decks and system options.

If you have any questions about custom bottle sizes, rotation speeds or standard systems do not hesitate to contact your DWK Life Sciences representative.

R — R2P™ 2.0:

Advanced touch screen with remote

communications and alarms

S — STANDARD: LED display

T — Top mounted:

ideal for rigorous cleaning and ceiling mounted connections

B — Bottom mounted:

easy access; floor mounted connections

P — Production (6”/152 mm):

smaller spacing between decks for more bottles per area

M — Modular (7.125”/181 mm):

larger spacing between decks to allow easier removal and replacement of bottles

F — Fixed size with a single piece uprights used for production and lighter weight due to less hardware

R — Removable decks for flexible design

SINGLE COMPONENTS AND REPLACEMENT PARTS

Ordering information

| Description | Cat.no. |

|---|---|

| WHEATON® Standard Roller Top Drive System Options with Belt Break Alarm and Battery Backup | W348890V2 |

| WHEATON® Standard Roller Bottom Drive System Options with Belt Break Alarm and Battery Backup | W348891V2 |

| WHEATON® R2P™ 2.0 Roller Top Drive System Options with Battery Backup and Temperature Sensors (Belt Break Alarm is already included with unit) | W348892V2 |

| WHEATON® R2P™ 2.0 Roller Bottom Drive System Options with Battery Backup and Temperature Sensors (Belt Break Alarm is already included with unit) | W348893V2 |

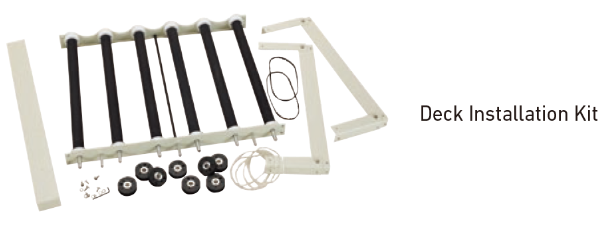

| Deck Installation Kit for Modular (7.125") Spaced System (Units have a maximum capacity of 9 decks) | W348887 |

| Deck Installation Kit for Production (6") Spaced System (Units have a maximum capacity of 11 decks) | W348889 |

ROLLER OPTIONS INFORMATION [7]

Belt Break Alarm

The Belt Break Alarm employs two magnetic sensors to ensure that all main pulleys are rotating on the unit. This is included on all R2P™ 2.0 Roller Apparatus.

Battery Backup

The Battery Backup protects cells during transport, processing and power outages. The unit automatically and seamlessly switches over to battery power to provide rotation for 8 – 18 hours. Bottom mounted control systems house larger, longer lasting batteries.

Temperature Monitoring/Alarm Option

This option includes two precision temperature probes for real time temperature monitoring and deviation alarms. The temperature is displayed in the temperature calibration screen or on the screen saver for quick confirmation of optimal operating conditions.

Creating a part number:

W + [1] + [2] + [3] + [4] + [5] + [6] + [7] - [*]

Example: WRBPF5110-C

WHEATON® R2P™ 2.0, bottom mount, production, fixed, 5-areas, 11-decks, no-options, plug style Europe

5 — Five placement areas per deck allows for use with an upright incubator

8 — Eight placement areas is used for large scale production type installations

01–11 — Production spaced units have a maximum of 11 decks

01–09 — Modular spaced units have a maximum of 9 decks

0 — No options included

1 — Options included

Standard Roller: Belt break alarm and battery backup

R2P™ 2.0: Temperature monitoring and alarms (2 probes) and battery backup (belt break alarm is already included)

-A — North America, 120 V

-B — Japan, 100 V

-C — Europe, 230 V

-D — UK, 230 V

-F — Australia/China, 240 V

-G — Italy/Chile, 230 V

-J — India, 230 V

STANDARD &

CO2 INCUBATOR

APPLICATIONS

- Cell cultivation

- Temperature dependent studies

- Larger R&D facilities

- Large-scale production

- To use with WHEATON® Roller Apparatus

FEATURES & BENEFITS

- Available as Standard or CO2 Incubator

- Designed specifically for use with

WHEATON® Roller Culture Apparatus - Compatible with:

- Production-spaced R2P™ 2.0 and Standard rollers with up to 11 decks

- Modular-spaced R2P™ 2.0 and Standard rollers with up to 9 decks

- Independent over-temperature safety protection

- Designed for temperature uniformity

- Large viewing window in the door (with an option for dual windows)

- Conforms to UL, CSA, and CE Standards

- Dry contact alarm port available for communicating alarm activation instances

- Internal electrical outlet for accessories

- USB port and analog 4–20 mA jack included for data logging temperature levels

- User configurable shelving system and roller apparatus guide tracks (shelving sold separately)

CO2 INCUBATOR ONLY:

- Infrared sensor technology to maintain 0 to 20% CO2 concentration

- Stainless steel interior

LINE諮詢

LINE諮詢  02 2684 1142

02 2684 1142